We're Open! Now Producing Signage

get a free quote

Carlsbad Signs

RATED 5.0 STARS

Rated 5 out of 5

(Based on 30 Client Reviews)

We Accept:

Client Review

Rated 5 out of 5

Wonderful experience!

“If I could give more than five (5) stars, I would! My experience with Signs for San Diego was nothing less than exceptional from start to finish. As a Project Manager for one of Gable’s largest clients, I expect our vendors to deliver high-quality product and/or services.”

Jessica Wurtzer

Jessica Wurtzer

Sign Types

- ADA Exit Signs

- ADA Staircase Signs

- ADA Unit ID Signs

- Banners

- Blade Signs

- Building Signs

- Business Park Monument Signs

- Channel Letter Refaces

- Church Signs

- Commercial Signage Gallery

- Commercial Tenant Panels

- Custom Sign Cabinets

- Dimensional Sign Letters

- Electronic Message Centers for Shopping Malls

- Fast Food, Takeout, and Drive-Thru Signs

- Foam Core Monuments

- Front Face Channel Letters

- Halo Channel Letters

- Interior Wayfinding Signs

- Lobby Signs

- Legal Compliance Signs

- Parking Signs

- Lobby Signs

- Mural Signage

- Neon To LED Conversion

- Plaque

- Post and Panel Signs

- Pylon Signs

- Repair and Service

- Restaurant Signs

- Retail Sign Faces

- Sand Blast Signs

- Shopping Mall Monument Signs

- Swimming Pool Signs

Client Review

Rated 5 out of 5

We couldn’t be happier!

We got both of our restaurant signs from them, and we couldn’t be happier! They were affordable, had incredible customer service, and the quality of their product matches their customer service! They even took care of some of our street light issues at no additional charge since they were already on-site with the lift!

They have a new customer for life!

-Brad S

Businesses Served

- Attorney Office Signs

- Automotive Dealership Signs

- Bank Signs and More

- Business Park Signs

- Church and Chapel Signs

- Credit Union Signs

- Dental Office Signs

- Franchisee and Franchiser Signs

- Hospital Signs

- Hospitality and Hotel Signs

- Law Firm Signs

- Military Signs

- Medical Office Signs

- Restaurant Signs

- Retail Shop Signs

- Strip Mall Signs

- Swimming Pool Signs

- Synagogue Signs

Subtrates and Materials

- Aluminum use in Signage

- ACM DiBond

- Acrylic Signs

- Castings Materials for Plaques

- Foam use in Signs

- Glass use in Signs

- HDU for Signs

- Laminates in Signs

- MDO Engineered Plywood

- Paper is Signage

- Plywood and Engineered Materials

- Polycarbonate and Lexan

- PVC as a Sign Material

- Stucco and Signs

- Scrim Banner

- Steel and Aluminum

- Vinyl use in Signs

- Wood for Sandblasting

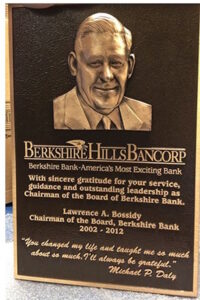

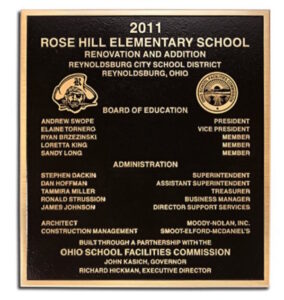

Brass and Bronze Plaques

When you need a plaque, you have some choices to make. Here are the 5 questions and answers you need to know before buying a plaque to last into the next millennium.

Materials: The 2 most common materials are Brass and bronze. In some cases glass is an alternative as well

Plaque Gallery

Brass and Bronze

Brass is a copper and zinc alloy that melts at about 900C. Brass is commonly used for door knobs, plumbing, gars, and plaques. It is yellow – like gold

Bronze is copper and Tin alloy (with trace additives of silicon and manganese) that melts at about 950C. This is a more durable choice and good for ships or seaside use. You see this material in ship fittings, props, bearings, sculptures and plaques. It is reddish.

Manufacturing techniques

Etched Plaques. The etching process lets us make the highest level of detail in the metal. It uses a photo mask that blocks the etching solution and leaves areas that are untouched and others are removed. The more time the etching solution stays on the metal, the deeper the removal. It is extremely precise. It is the best choice for very smaller letters and photos. Incredible “picture-perfect” precision is used in museum exhibits, front office identification, dedication and recognition plaques. They are durable and can be used outdoor

Cast Plaques

The metal is normally bronze. In some cases aluminum casting may be available. A sand mold is made with the text and graphics. The mold can also use wood or a polymer. Once the pattern is made, a fine sand/epoxy mixture is poured around and over the pattern. This is called the “investment”. It is packed down and the pattern is removed leaving the image of the pattern in the sand. Molten bronze is poured into the pattern, cooled and then the rough plaque is formed. This have a unique look, can have a sand texture, curves and require patterns that allow for the pour to flow.

Precision Machined Plaques

We use a computer generated pattern with the letters and other features in 3D. Taking this pattern to a CNC router we translate this to a machine readable form. Starting with a blank metal sheet (1/4”, 5/16” thicknesses are common) we use a CNC router to cut away the parts not needed. This have a different look and feel compared to the etched or cast plaques.

Brass and Bronze Plaques are ideal

Brass and Bronze Plaques are ideal for contractors, architects, landscape artists, and corporate clients. They use these in Churches, Synagogues, government buildings, schools, historic buildings, parks, universities, memorials and dedications.

Need a metal plaque? Give us a call 760-730-5118

Plaque Gallery

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo

GET A FREE QUOTE

If you have any questions or comments please fill out the following form and one of our representatives will contact you as soon as possible.